Affordable Mold Removal Surrey

Looking for professional mold and asbestos specialists in Surrey right now? We quickly assess, isolate, and remediate hazards using WorkSafeBC/BC OHS-approved methods, negative-pressure HEPA containment, accurate air and moisture monitoring, and documented chain‑of‑custody sampling (PLM/TEM). We identify causes (leaks, humidity >60%), clear contaminated materials, apply EPA-registered antimicrobials, and maintain moisture to 40-50% RH to prevent recurrence. For pre-1990 suspect ACM, we execute wet methods, glove‑bag/full enclosures, and TDG‑compliant waste transport. Complete with insurance coordination and defensible clearance-let us explain what this means.

Main Insights

- Fast emergency triage in Surrey: isolate utilities, establish hazard zones, install negative-pressure containment to minimize mold amplification and asbestos disturbance.

- Certified surveys for pre-1990 buildings: comprehensive sampling with complete custody tracking, laboratory PLM/TEM testing, and accurate measurement per WorkSafeBC and CSA guidelines.

- Mold remediation: professional extraction of compromised porous materials, followed by HEPA vacuuming, treatment with EPA-registered antimicrobials, and carefully controlled dehumidification to sustain 40-50% RH.

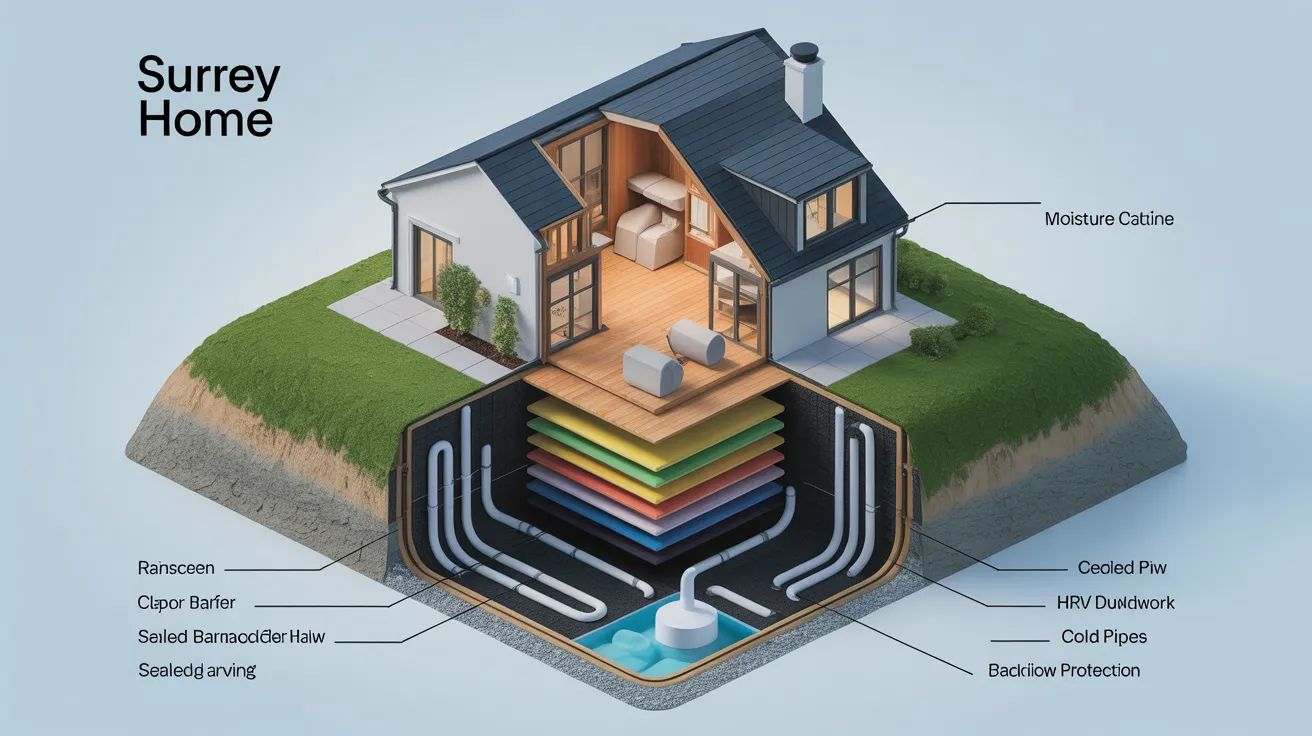

- Moisture control and prevention: resolve leak issues, ensure correct drainage slopes, integrate rainscreen systems, implement vapor protection, add proper insulation, implement HRV ventilation systems, and maintain recommended air exchange rates.

- Asbestos abatement: performing thorough containment procedures using containment methods like glove-bags and full enclosures, combined with wet procedures, HEPA filtration, regulated waste transport with labeling, and comprehensive air testing before, during, and after.

Mold and Asbestos: Pressing Concerns in Surrey

Given Surrey's damp marine climate, deteriorating building stock, and current infill development create ideal conditions for concealed hazards, mold and asbestos require prompt attention. You face elevated moisture content that promote mold development in structural cavities, crawlspaces, and bathrooms, while pre-1990 materials potentially harbor degradable asbestos in insulation, flooring, and textured coatings. Both hazards carry established respiratory and carcinogenic risks, affecting Community health and burdening healthcare resources.

There's also legal liability. WorkSafeBC regulations require thorough hazard assessment, controlled removal, and proper record-keeping. Noncompliance results in stop-work orders and fines, and puts insurance protection at risk. Proactive assessment and compliant remediation safeguard inhabitants, maintain property worth, and keep projects on track. Operating expenses decrease by avoiding building damage, spread of contamination, and legal issues.

When to Seek Professional Inspection and Testing

Although certain problems may seem insignificant at first, key markers in Surrey's buildings call for professional inspection and lab analysis. If you notice visible discoloration on drywall, ceiling tiles, or foundation walls-especially spreading stains or efflorescence-you should sample and verify. Persistent odors (moldy, natural, or bitter) indicate biological activity or VOCs; don't mask them-record and analyze. Recurrent moisture events, high indoor humidity (>60%), or condensation on windows suggest environments conducive to concealed mold growth. In buildings constructed before 1990, loose insulation, degrading ceiling surfaces, or cracked vinyl tiles indicate potential asbestos presence; consider them hazardous until tested. When residents experience breathing problems, headaches, or worsening asthma, escalate to professional air and bulk sampling adhering to WorkSafeBC and CSA protocols.

Our Comprehensive Mold Remediation Protocol

After inspection and testing confirm mold, we execute a controlled, standards-compliant remediation workflow. Initially, we map impacted surfaces, moisture sources, and pathways. Subsequently, we establish containment barriers with negative air pressure and HEPA filtration to avoid cross-contamination. We confirm pressure variations and airflow control with monitoring devices and smoke verification.

Source removal takes precedence over encapsulation: porous materials are cut and bagged, then wire-brush, scrape, and HEPA-vacuum all remaining surfaces. Our treatment includes EPA-registered antimicrobials selected for specific substrates and contamination loads. We address moisture concerns by drying to specific EMC targets, implementing data-logged dehumidification with balanced air circulation.

We perform thorough cleaning beyond the containment, including vents and high‑touch areas. Post-cleanup verification consists of visual clearance, particulate metrics, and third‑party sampling as mandated by local guidance or client specifications.

Professional and Reliable Asbestos Inspection and Abatement

Prior to sample collection, you obtain a standards-based plan meeting WorkSafeBC, OHS, and EPA/AHERA standards that defines suspect materials, access controls, and chain‑of‑custody. We assess all types of hazardous materials, employ negative pressure containment, and deploy appropriate glove‑bag or full enclosure procedures according to risk. You'll observe calibrated air monitoring pre‑work, during disturbance, and following remediation to ensure adequate fiber control.

Our sampling process involves material samples using sanitized sampling methods, sealed containment media, and complete custody tracking. Professional analysts conduct microscopy analysis using polarized light or TEM, and we issue analysis data following lab verification verifies analytical precision and detection thresholds. For removal procedures, we utilize moisture-controlled techniques, HEPA‑filtered extraction, and secure waste management with secure, labeled transportation. Completion verification integrates thorough visual examination and quantitative air testing criteria.

The Standards, Regulations, and Certifications We Adhere To

You need assurance that qualified professionals are on site, so we maintain industry-recognized certifications (like IICRC for mold, AHERA/NIOSH-aligned asbestos training) supported by current documentation. We comply with provincial and federal requirements, including WorkSafeBC, BC OHS Regulation Part 6, and applicable federal asbestos and hazardous materials rules. We implement rigorous safety protocols-comprehensive site safety evaluations, controlled pressure containment, atmospheric testing, properly fitted protective equipment, and documented clearance criteria.

Industry-Recognized Certifications

Although every project is different, our compliance framework remains consistent: we strictly implement industry-recognized certifications and required protocols. Our clients benefit from technicians certified to ANSI/IICRC S520 for mold remediation, including thorough containment, negative pressure, and clearance criteria. Our supervision team maintains Asbestos Supervisor credentials, and field teams receive hazard-awareness training aligned with current control guidelines. We verify indoor air quality controls through IAQ Certification, incorporating instrument calibration, baseline sampling, and post-remediation verification.

Additionally, you'll find Lead Accreditation displayed on our profiles, demonstrating expertise in safe lead handling procedures, dust management, and waste handling. Our respirator fit test documentation, medical approvals for respirator use, and documentation trails are preserved for compliance verification. We systematize work with safety evaluation protocols, environmental monitoring, and verifiable training matrices, guaranteeing your site complies with comprehensive, evidence-based standards.

Provincial and Federal Compliance

Because regulatory compliance is essential, our solutions conform to British Columbia's Workers Compensation Act and WorkSafeBC OHS Regulation (Part 5 Asbestos, Part 6 Contaminants, exposure control plans), Hazardous Waste Regulation, and BC Building Code requirements, along with federal frameworks including the Canada Labour Code Part II, Hazardous Products Act/WHMIS 2015 (GHS), CEPA/PCB and hazardous substances provisions, and Transportation of Dangerous Goods (TDG) for waste movement. We provide verifiable documentation: exposure control plans, hazard assessments, inventory logs, chain-of-custody, and TDG shipping papers. We track Regulatory updates, adopt harmonized SDS/labeling, and adjust instruments per manufacturer and ISO guidance. You'll see permitting coordination with municipalities, landfill acceptance criteria verification, and defensible record retention. We also provide guidance about Funding programs that reduce compliance-driven abatement and disposal costs.

Advanced Safety Guidelines

Even before operations begin, crews follow a documented safety management system that integrates CSA, ANSI, and WorkSafeBC standards into workplace controls. You are provided with a site-specific exposure control plan, risk evaluation, and isolation protocol based on NIOSH and EPA best practices. We ensure qualified supervision, certified respirators, and verified air monitoring instruments according to manufacturer guidelines and ISO/IEC 17025 lab certification.

You'll find containment using negative pressure and HEPA filtration tested to IEST standards, controlled isolation of HVAC, and regulated waste management under TDG. We implement personal protective equipment based on risk assessment: half-face and full-face APRs, P100 filters, disposable protective wear, and decon protocols with clean and contaminated area divisions. Documentation includes transfer documentation, routine clearance verification, and post-project sampling measured against WorkSafeBC exposure limits and final clearance standards.

Fast Emergency Response and Insurance Assistance

Act quickly when environmental hazards compromise indoor air quality-early intervention and containment measures reduce mold growth and asbestos disturbance. You'll gain advantage through emergency assessment that emphasizes life safety, utility isolation, and hazard zoning, followed by negative air containment, HEPA filtration, and Category 1-3 analysis to guide material removal. Certified technicians obtain verifiable moisture and particulate readings, document suspect ACM, and, where necessary, pause for bulk sampling under WorkSafeBC and EPA NESHAP thresholds.

Our immediate service features an insurance liaison who aligns scope, photos, chain-of-custody, and Xactimate estimates according to policy specifications, deductible amounts, and coverage conditions. We arrange property assessments, generate progress documents, and keep regulatory records. You obtain precise timeframes, clear cost breakdowns, and well-documented remediation processes that helps secure claim authorization.

Strategies for Long‑Term Moisture Prevention

While rapid intervention manages pressing issues, durable outcomes hinge on addressing moisture problems and stopping conditions supporting mold development and asbestos exposure. You'll need to implement a comprehensive approach: improve slope and water flow, isolate foundation penetrations, and ensure roof and plumbing integrity. Utilize continuous humidity monitoring to sustain interior RH at 40-50%; integrate smart sensors with warnings and performance monitoring. Install balanced ventilation and HRVs, validate ACH through ventilation measurement, and seal ductwork. Apply appropriate vapor barriers on the climate-controlled side according to BCBC guidance; match with exterior rain screens and capillary breaks. Cover cold surfaces to eliminate condensation. Add sump systems with backflow protection. Record control parameters, maintenance schedules, and documentation for records. Revalidate controls quarterly and following modifications.

Questions & Answers

How Do Your Warranties and Service Guarantees Work After Remediation

The warranty protection encompasses defined scopes after remediation, with warranty terms dependent on addressing root causes and following IICRC S520 protocols. You'll get complete documentation, clearance testing, and planned follow-up visits to ensure no recurrence and standard compliance. If conditions recur within the warranty period and the original issue was resolved, we offer no-cost reinspection and targeted retreatment. Coverage doesn't include new water intrusions or altered conditions. We can arrange third-party verification to maintain regulatory defensibility.

What Payment Plans and Financing Options Do We Offer for Large Projects?

We offer flexible payment choices that are both compliant and transparent. Our lending options include set annual percentage rates and come with no prepayment penalties and clear amortization schedules. You have access to staged draws connected to construction checkpoints, as well as electronic and card payment options, and HCSA/FSA where applicable. Our team performs comprehensive checks on personal details, earnings, and work specifications, follow all TILA disclosure requirements, and offer digital document execution. Decisions on pre-approval typically come within minutes, contingent on underwriting approval.

Will We Need to Vacate, and for How Long During Work?

You will likely need temporary accommodations during the cleanup procedure. For asbestos, regulatory requirements mandate full containment, negative pressure, and clearance air testing; plan for relocation lasting 1-3 days for limited zones, 3-7+ days for bigger affected areas. For mold, IICRC S520 recommends isolation and HEPA remediation; occupancy is possible if the work zone is properly sealed, but temporary accommodations should be considered for occupants with sensitivities. Length of work depends on the area size, material types involved, and clearance testing schedule.

What Steps Are Taken to Protect Pets and Valuables During Remediation?

We secure your pets and personal possessions by implementing isolated work zones, arranging pet relocation, get more info and storing items securely. Imagine it as a professionally coordinated beehive transfer - organized and managed. We coordinate pet relocation to off-site care facilities or a protected safe room with advanced HEPA filtering. For possession safeguarding, we securely package non-porous items, discard affected porous materials, and maintain detailed chain-of-custody. Our certified technicians adhere to EPA/OSHA and IICRC S520 protocols: maintaining negative pressure, setting up polypropylene barriers, constructing decontamination chambers, and confirming proper air circulation before authorizing return.

Will You Manage the Permit and Strata Approval Process?

Yes. You authorize us, and we handle all permitting and strata communication throughout the entire process. We assess requirements, identify relevant regulations, and develop regulatory documentation (drawings, MSDS, abatement plans). We obtain municipal permits, book inspections, and keep comprehensive records. For strata, we adhere to strata regulations, deliver notice packages, join council sessions, and obtain formal authorization. We provide you with a clear timeline, progress reports, and authorizations, ensuring compliance with regulations, reduced interference, and complete documentation.

In Closing

Act now to secure your compliance, health, and property. Upon spotting concerning signs like dampness, staining, or suspect materials, arrange for professional assessment and treatment before small concerns become significant challenges. We strictly adhere to CSA, IICRC S520, and WorkSafeBC standards, implementing negative pressure and HEPA filtration, while maintaining detailed records of every phase for insurance purposes. You can expect quick response times, certified chain-of-custody lab results, and comprehensive post-remediation verification. Maintain safety through adequate moisture control, enhanced ventilation systems, and regular inspections-keeping issues at bay.